Explosion Proof Differential Pressure

0-10″ H2O to 0-300 PSID

- Class 1, Div. 1 rated enclosures

- Rugged, weatherproof design

- Gauges, switches and transmitters

- Popular for hazardous environments

Model |

DP Range Min |

DP Range Max |

Max Line Pressure |

Max Line Temperature |

Accuracy |

Electrical Availability |

Specifications, |

|---|---|---|---|---|---|---|---|

1204 PGS/PS/PGT/PT |

PSID 0-5 |

PSID 0-150 |

5000 psig |

176°F (80°C) |

2% |

1 or 2 Switches |

|

1504 DGS/DS/DGT/DT |

PSID 0-10 |

PSID 0-300 |

3000 psig |

176°F (80°C) |

2% |

1 or 2 Switches |

|

1514 DGS/DS/DGT/DT |

PSID 0-1 |

PSID 0-50 |

1500 psig |

176°F (80°C) |

2% |

1 or 2 Switches |

|

1804 DGS/DS/DGT/DT |

PSID 0-0.4 |

PSID 0-8 |

150 psig |

176°F (80°C) |

2% |

1 or 2 Switches |

D=Diaphragm G=Gauge S=Switch T=Transmitter P = Piston

Hazardous Location Differential Pressure

When it comes to measuring high pressure differentials, accuracy and reliability are critical. Hazardous location, high pressure differential pressure gauges measure the pressure difference between two points. Acting in the place of two pressure gauges, these units allow for one simple reading on an easy-to-read scale. Popular in filtration, flow and level applications, they are a low cost alternative to bourdon tube and bellows designs.

These hazardous location differential pressure instruments are used in environments containing hazardous vapors, gases or particulates. The switches and electrical connections are housed in special UL, CSA, FM and ATEX approved enclosures. The cast aluminum housings have two mounting lugs, a 3/4″ NPT electrical conduit port, and meet the following specifications: Class 1, Gr. B, C, & D; Class II, Gr., E, F, & G; and Class III. They also meet NEMA 3, 4X, 7, 9, & 12 specifications.

We offer our high pressure, explosion proof differential pressure gauges with bodies (and wetted parts) of aluminum and stainless steel. A variety of dial sizes are also available, from 3.5 inch to 6 inch, with many porting and mounting configurations. Choose from a wide selection of standard options; enough to satisfy any requirement.

The robust construction of Orange Research’s high pressure, explosion proof differential pressure gauges withstand intense pressure vibration, helping to ensure reliable performance and safety. Trustworthy measurements, even in extreme environments, improve process control and while minimizing costly errors, downtime and potential risk to operators and equipment.

Leverage our explosion proof differential pressure expertise and speak with a member of our team today.

WARNING: This product contains Nickel, a chemical known to the State of California to cause cancer. For more information go to: www.p65warnings.ca.gov

Switches, Relays, Transmitters

A variety of reed switches, relays and transmitters can accompany the differential pressure gauges or be supplied on their own, without a dial. SPST switches are offered normally open (N.O.) or normally closed (N.C.). SPDT reed switches also are available. DPDT relays are offered for high inductance applications, such as those incorporating motors or solenoids. Transmitters offer a current or voltage output. Contact us for more information on switches, relays and transmitters.

Contact Us About Customized Options for Explosion Proof Differential Pressure Gauges

Built to withstand harsh environments and demanding pressures, our explosion proof differential pressure gauges offer exceptional durability and long-lasting performance for a variety of industries, including oil and gas, chemical processing, power generation, hydraulics, and more.

Our flow measurement and differential pressure gauge manufacturing experts understand that no two applications are alike. We offer a range of customization options, from pressure ranges and materials to specialized outputs and markings, to ensure your gauge fits your needs. Contact our team to discuss your unique specifications.

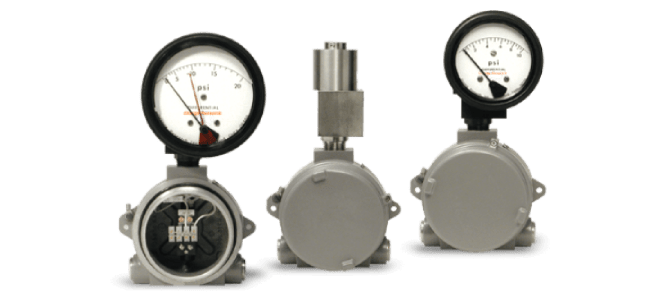

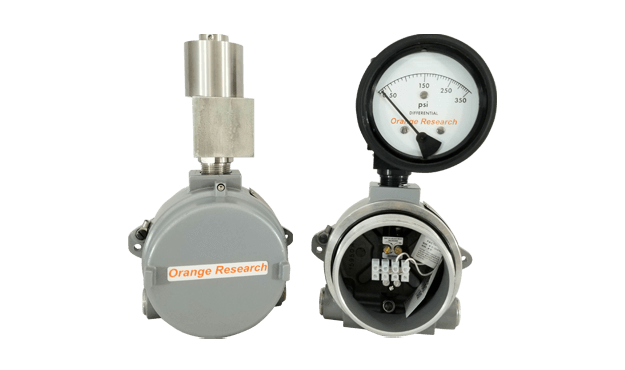

Photos: Explosion Proof DP

Explosion Proof Family

1804 Electronics

1504 Electronics

WARNING: Some of our products contain Nickel, a chemical known to the State of California to cause cancer. For more information go to: www.p65warnings.ca.gov

WARNING: Some of our products contain Nickel, a chemical known to the State of California to cause cancer. For more information go to: www.p65warnings.ca.gov