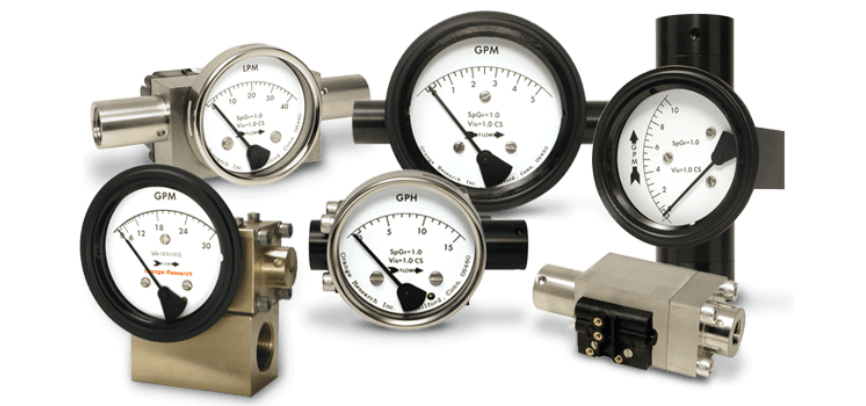

Flow & Differential Pressure Applications

Range of Sizes and Materials for Any Application

- Liquids & gas monitoring

- Low pressure, high pressure & explosion proof models

- Specific designs for differential pressure applications and 50 years of manufacturing differential pressure gauges and flow gauges

Orange Research pressure and flow products are designed to meet even the most rigorous flow and differential pressure applications. If you don’t see your market listed here, contact us – we likely manufacture gauges, transmitters and switches that meet your needs.

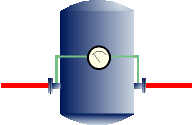

Filters/Strainers

Pressure drop across filter or strainer informs the operator when it’s time to replace, backwash or bypass filter elements. Monitoring prevents servicing too late or too early. Clean and dirty scales are popular. Our gauge switches can be used to automatically initiate cleaning at a specific setpoint. Read More on Differential Pressure Filtration.

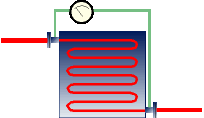

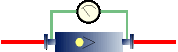

Differential Pressure Flow

Flow scale based on differential pressure is popular on venturi, orifice plates and other primary flow elements. This approach is an inexpensive and accurate alternative for large and small pipes. Specify the differential pressure that the flow rate is based on when ordering. Read More on Differential Pressure Flow.

Oil & Gas

Differential pressure, filtration and flow indicators for oil and gas industry applications. We are the leader in differential pressure gauges, switches and transmitters where lower cost solutions are required. Read More on Oil & Gas Applications.

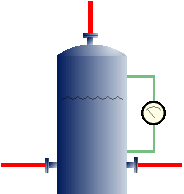

Liquid Level & Cryogenic Level Measurement

Pressure differential between bottom and top of tank allows for level readings on pressurized tanks. Popular in cryogenics and other liquid systems. Gauge scales can read in percentage filled or height of fluid. Specify specific gravity of fluid and height of tank when ordering. Read More on Cryogenic Tank Level Gauges.

Hydraulics

Differential pressure filters and sensors built for reliability in the harsh environments of hydraulic equipment. Orange products precisely perform in these high temperature, high vibration, shock-prone and difficult environments. Read More on Pressure Differential for Hydraulic Filters.

Heat Exchangers

Pressure drop across heat exchangers indicates problem conditions such as scale or debris buildup. Monitoring improves efficiency by alerting operator of problem conditions so that proper temperature and flow rate can be maintained.

Backflow Prevention

Used in backflow prevention test kits, our gauges are popular for testing backflow prevention valve operation. Pressure drop is an indication of valve performance. Regular monitoring of these valves ensures the safety of public water supply.

WARNING: Some of our products contain Nickel, a chemical known to the State of California to cause cancer. For more information go to:

WARNING: Some of our products contain Nickel, a chemical known to the State of California to cause cancer. For more information go to: