Dial Cases, Mounting Brackets And Standard Options

Differential Pressure and Flow Gauges

- Basic and flanged options

- Stainless steel or cast and machined aluminum, anti-corrosion coated & black painted finish

- Weather resistant

- Mini DP Indicators available

B “Basic”

This case is the most popular choice since the gauge is often supported by the process line. An optional c-clamp is offered for panel mounting.

F “Flanged”

This case has holes for panel mounting. Two or three holes are drilled in the flange to accept screws for flush mounting to the panel.

Miniature Differential Pressure Indicators

Our miniature differential pressure indicators come standard with a weatherproof 1″ molded lens. A special 2.5″ dial also is available.

Weather Resistant

All of our cases are weather resistant. This feature also facilitates liquid filling, which is an option available on all standard gauges.

Dial Case Materials

(these materials represent dial case only, not the pressure body):

- 2.5″ & 6″ Dials: stainless steel

- 3.5″ & 4.5″ Dials: cast and machined aluminum, anti-corrosion coated & black painted finish

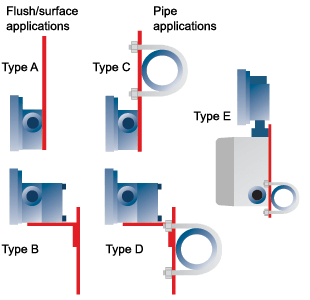

A variety of brackets are available for mounting differential pressure gauges on walls, panels and pipes.

Surface plates flush mount instruments without external switches. Some have extended angle brackets to hold models with Nema 4X switch or relay enclosures.

Pipe clamps mount units to various size rods or pipes. Flanged dial cases and c-clamps offer panel mounting options.

Differential Pressure Gauge Mounting Brackets

| Description | Suitable for Model Number |

|---|---|

| Flush/surface mounting brackets | |

| Type A | 1201, 1502, 1516 |

| Type B | 1203, 1533, 1800 series |

| Pipe mounting brackets (specify pipe size) | |

| Type C | 1201, 1502, 1516 |

| Type D | 1203, 1533, 1800 series |

| Type E | For hazardous location models 1204, 1504, 1514, 1804 |

Standard Options

Gauge and Lens Options

- Plastic lens

- Shatterproof lens (n/a on 2.5″)

- Liquid filling, glycerine

- Follower pointer

- Epoxy-coated dial case (n/a on 2.5″ & 6″)

- Lexan B style dial case (2.5″ & 3.5″ only)

- C-clamp

Special Dial Options

- Red arc

- Multi-color arc

- Dual scale

- Square root flow, single scale

- Square root flow, dual scale

- Non-catalog ranges

- Clean/dirty dial

- High-density dial (4.5″ min.)

- Service legend (one line)

- Dial artwork, B&W (1 time charge)

- Dial artwork, 2-color (1 time charge)*

*Need Pantone reference and sample or file

Alternate Port Sizes*

- 1/8″ NPT

- 1/2″ NPT

- MS

- BSP

*Many types avail., contact factory

Elastomers

- Buna-N o-ring seals

- Viton o-ring seals

- EPDM o-ring seals

- Fluorosilicone o-ring seals

- Teflon o-ring seals

- Buna-N diaphragm and o-ring seals

- Viton diaphragm and o-ring seals

- EPDM diaphragm and o-ring seals

- Fluorosilicone diaphragm and o-ring seals

Miscellaneous Options

- Teflon-coated magnet/spring

- Calibrate on steel

- Oxygen service (oxygen cleaned)

- High temperature service

- Stainless steel tag (with SS wire)

- Paper tag

- Reverse pressure

- Teflon-coated spring* (flow meters)

- Teflon metering cone (flow meters)

- Reverse flow (flow meters)

- Vertical flow (flow meters)

- Special calibration (flow meters)

*Magnet is always Teflon coated on flow meters

Certification Options

- Certification of Conformance

- Certification of Accuracy

- NACE Conformance (MR0175)

- Material Certification

- Certified Drawing

- Certificate of Origin

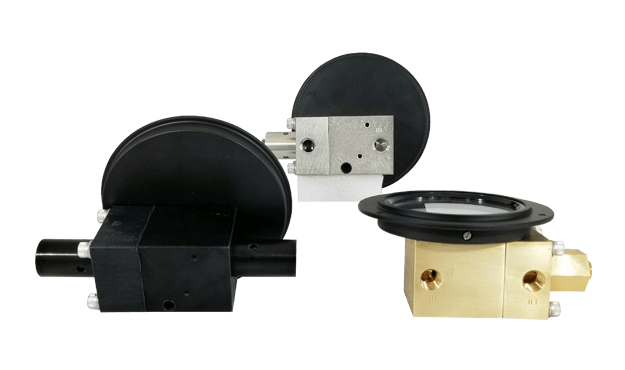

Photos: Dial Cases

Dial Case Family

1201 Dial Cases

1516 Port Options

WARNING: Some of our products contain Nickel, a chemical known to the State of California to cause cancer. For more information go to:

WARNING: Some of our products contain Nickel, a chemical known to the State of California to cause cancer. For more information go to: